Pyrolysis

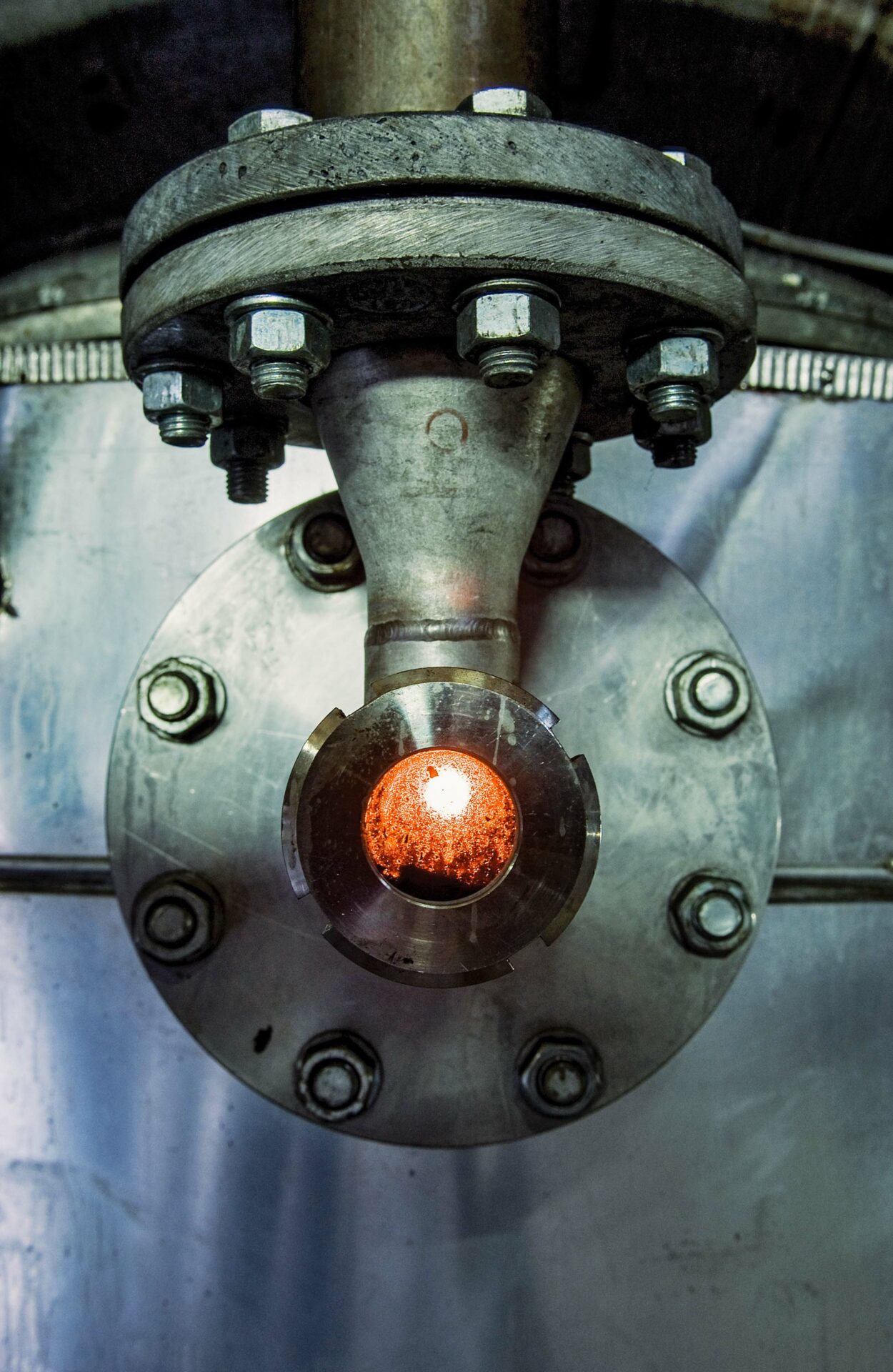

Pyrolysis reactor is designed to fully convert raw biomass into clean biochar, with precise control of pyrolysis conditions.

- NOTAR® advantages:

- Autothermal process

- Precise temperature field and residence time

- Production of clean “tar free” biochar

- Gaseous tar mainly composed of primary tar